Effect of dry ice velocity on surface quality

Time:2023-09-11 Category:【DSJet technology】Read:293

The dry ice impact velocity represents the distance that the dry ice nozzle moves relative to the stationary package per unit time. The impact velocity mainly affects the number of dry ice particles reaching the cutting sidewall surface per unit time and the operational efficiency, which are important factors influencing the treatment effectiveness. A lower impact velocity results in a higher number of dry ice particles impacting the surface per unit area and unit time, generating stronger particle explosive forces and facilitating the removal of surface impurities. However, excessively low velocities not only reduce operational efficiency but also cause significant damage to the solder resist layer. Therefore, controlling the dry ice impact velocity is of great significance for improving the surface quality of semiconductor packages.

Under constant conditions for the remaining parameters, the influence of dry ice impact velocity on the treatment effectiveness was determined through experiments. As shown in Figure 5a, the impurity content in both the encapsulant and PCB regions gradually increases with an increase in impact velocity, which is opposite to the effect of jetting pressure. Figure 5b shows that the solder resist layer damage rate decreases with increasing velocity. When the velocity exceeds 40 mm/s, the decrease in the damage rate becomes slower and stabilizes at approximately 0%, indicating that the dry ice impact force on the material surface is not sufficient to cause further damage to the microcracks in the PCB. Considering the residual Cu impurity content on the material surface and the damage rate of the solder resist layer, the optimal dry ice impact velocity is determined to be between 40-50 mm/s.

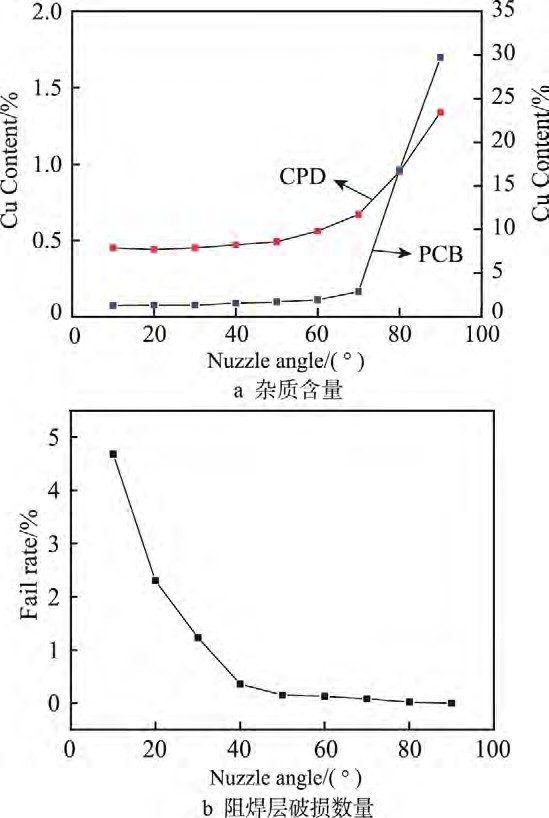

The jetting angle primarily affects the damage rate of the solder resist layer. This is because microcracks on the PCB surface have a certain directionality. The smaller the jetting angle, the more perpendicular the microcrack direction is to the impact direction, resulting in an easier formation of larger cracks and subsequent detachment of the solder resist layer. Conversely, as the jetting angle increases, the impact force on the microcracks becomes more parallel to their direction, reducing the force exerted on the microcracks and making it less likely for the cracks to expand. In this experiment, the package samples were positioned horizontally, and the dry ice nozzle was tilted at different angles for jetting. The effect of the jetting angle on the removal of impurities is shown in Figure 6a. When the jetting angle is less than 70 degrees, the surface Cu impurity content remains low, indicating a significant effect on impurity removal. However, when the jetting angle exceeds 70 degrees and continues to increase, the Cu impurity content suddenly and significantly increases, approaching the level of uncleansed samples.